Relays are devices, controlled by an electrical signal, that open or close electrical contacts, allowing electricity to be switched either on or off in a circuit. They can be either energized and latched, or de-energized and unlatched. Simply put, ON or OFF.

In their basic engineering, relays are elegantly simple. They contain an electromagnet, some electrical contacts, an armature that can be controlled by a magnetic field, and a spring. The spring holds the armature in place. The electromagnet attracts the armature when a current is applied. The movement of the armature closes a set of contacts and current flows in the circuit. This allows a relay to control a high-current electrical load with a low-current electrical signal. This quality makes them useful for safely controlling power from a distance, and in a wide variety of devices and systems.

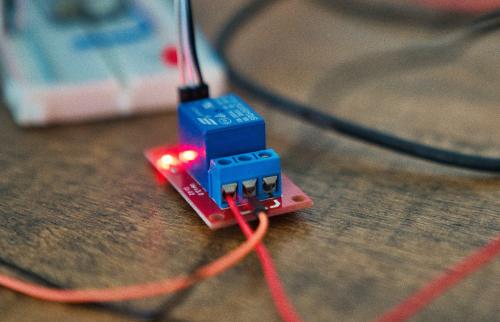

When a relay is normally open (NO), there is an open contact and the relay is not energized. When the contacts are normally closed (NC), there is a closed contact when the relay is not energized.

This pretty much describes the functional part of a relay that you can see and measure. Contacts opening and closing, current flowing, devices energized or not. At a more detailed level, however, other things are happening that can have impact on the performance of the circuit in which the relay is used.

When the relay is off, or not energized, the contacts are open, and no current flows. As the control current increases, the relay begins to move through its inactive phase. As the control current continues to increase, the relay moves into an inactive/active phase, causing it to uncontrollably cut on or off, or "bounce". Finally, increasing control current moves it into the active phase, with closed contacts and current flowing.

A similar process happens when the control current decreases, moving the relay from the active state to both active and inactive, or "dropout" state. Again, "bounce" can occur at this point. Finally it moves to the inactive or "restored state". This entire process takes just milliseconds, but the contact bounce that occurs can cause arcing, surges can flow through the circuit upon contact, and downgrade or breakdown in circuit performance can occur.

Despite this, relays are relatively robust devices that can be designed to operate dependably in a range of applications and environments. Their fundamentals and performance characteristics are well known and can be accounted for in

overall system design.

In devices that consume a lot of power, and that would normally require an extensive amount of wire to operate, a relay can be used with a single low-power wire to control the on/off electrical flow. In fact, since the circuit powering the relay is physically separated from the circuit powering the device, relays are commonly used where it’s impossible to have a direct connection between the control circuit and the output device, either because of risk to the equipment or the safety of the operator.

Relays also support a broad range of signal characteristics, from low to high voltage and current, and from DC to GHz frequencies. This makes it relatively easy to specify a relay with signal characteristics that match your system needs. The isolation of drive circuitry from the contacts, and the contacts from one another, also make relays ideal when galvanic isolation is required.

There are two broad types of relays: Electromechanical Relays (EMR), and Solid State Relays (SSR). Each of these types of relays have several subsets to fit particular applications.

EMRs work via the physical movement of internal components and are open or closed by a magnetic force when a current is applied.

EMR types include the following:

- General Purpose Relays are simply electromechanical switches that operate with AC or DC current, usually 12V – 230V, and control currents from 2 amps to 30amps.

- Machine Control Relays are heavy duty devices used to control starters and large industrial components. They are more durable than general purpose relays and can easily be combined with accessories to expand their functionality to include timing, latching control and transient noise suppression.

- Latching Relays have two states. They are set either ON or reset OFF by the input of voltage. The relay maintains this set or reset condition until it receives the next inverting voltage signal.

- Reed Relays are so-named because they consist of two reeds, hermetically sealed in glass to make them immune to contaminants, humidity or fumes. They are normally small, compact and fast operating with one contact (NO). In operation, the ends of the contact are closed by a magnetic force. Typically used to switch industrial components like starter motors, solenoids and contactors, reed relays are usually compact and fast operating.

SSRs are electronic switches that operate with no moving parts. They consist of an input circuit, a control circuit and an output circuit. SSRs accomplish the coupling between the input and output circuits via a control circuit, which is activated when a voltage higher than the relays specified pickup voltage is applied to the relays input. The relay is deactivated when the voltage applied is less than the specified dropout voltage. Common SSR voltage ranges are 3VDC to 32VDC, making them useful for electronic circuits.

SSR types include the following:

- Zero-Switching Relays turn ON the load when the control voltage is applied and the voltage of the load is close to zero. They turn OFF the load when the control voltage is removed.

- Instant ON Relays turn the load ON as soon as the pickup voltage is applied.

- Peak Switching Relays turn the load ON when the control voltage is applied and the voltage of the load is at its peak. They turn the load OFF when the control voltage is removed and the current in the load is close to zero.

- Analog Switching Relays have a circuit that controls the amount of output voltage as a function of the input voltage. This allows an infinite number of possible output voltages within the rated range of the relay. These relays turn OFF when the control voltage is removed and the load current is near zero.

- Optically Coupled Relays accomplish current switching in response to the on or off state of a light source (usually an LED). They are faster than electromagnetic relays and provide isolation between the control & power circuits.

Relay ratings indicate how much power can safely be switched through the relay. The rating is expressed as either AC or DC and usually given in terms of amperes. Amp levels must be as large as the rating of the target device.

Configuration is dependent on the number of things the relay can control simultaneously. With just one input and one output it is a simple on/off switch, or single throw. For two outputs, there are two throws. Pole and throw information is designated like this:

- Single pole, single throw: SPST

- Double pole, double throw: DPDT

- Three pole, double throw: 3PDT

- Single pole, three throw: SP3T

Relay contacts are either normally open (NO) or normally closed (NC), depending on the state that exists when no power is applied.

As you can see, a relay is a rather simple device that performs a very useful function, leading to a diversity of uses across products and markets. All relays operate in the same basic way, but a range of types exist to match selected applications, mountings and environments.

Relays are widely used to switch devices like heating elements, starter coils, alarms, pilot lights and motors, where switching speed is not of the highest concern. High power relays are used in electric vehicles and other transportation platforms. Relays can also control the maximum current and voltage that can go through the armature and contacts, the number of armatures used, the number of contacts used, and whether the contact is normally open or closed.

Modern relays are used in areas ranging from consumer electronics and home appliances to autos and transportation. They are employed in process control systems, from small to large. They function as motor controls and motor protection devices. They help control systems from as small as automatic garage door openers to large electric power systems. They have aerospace, defense and marine applications as well as in emergency standby power systems.

Collections of relays, as binary actuators, were used in the very first computers to execute Boolean (logic) gates. Even with this long history, it is difficult to imagine a modern product or system in which power is being directed or controlled that doesn’t use some type of relay.

The application of semiconductor technology in the relay sector has been the biggest driver of change over the past 10 years, utilizing smart power solutions in SSRs to reliably deliver high current. Digital technology has also allowed many more relay functions to be incorporated in a single hardware package. Plus, the spread of LED technology has led to improvements in optically coupled small signal solutions.